Cabinas para secado y venteado de ropa de trabajo y ropa de protección tipo SSO

CABINAS DE SECADO

Cabinas para secado y venteado de ropa de trabajo y ropa de protección tipo SSO

Página disponible en polaco e inglés

Drying cabinets are used as equipment for organizations operating on an ongoing basis – regardless of the season and atmospheric conditions. They are used for drying and ventilating of working clothing used at employees’ performing of everyday professional activities, in particular when works are performed outside.

APPLICATIONS

- Industry and services

- Recreational facilities for winter sports

- Disinfection

Rain and humidity make: working, protective clothing, as well as uniforms and boots in need of changing, and therefore – drying. This applies to, in particular, people working at various field structures and in the field, especially people performing supervisory, controlling and maintenance works – emergency and overhaul brigades performing repairs of electrical tractions, power lines, railway lines, roads, teams operating on an ongoing basis: at airports, guard posts, fire brigade stations, where contact with water reservoirs is frequent – pools, sluices, shipyards etc., where the natural weather and environmental conditions result in damping of working clothing or its excessive absorption of unpleasant and hazardous odors (e.g. in galvanization stations).

After finishing everyday work, working clothing, gloves, boots subjected to the process of drying and ventilating may be used once again.

We set the cabinet on an even surface, we do check out the level on the ground, we do mount spiro-pipe into the ventilation grille and then we connect the cabinet to a 230V socket.

Cabinet design - self-supporting, made of sheet steel, galvanized; painted, welded; double doors with lock. Attachments of the cabinet - made of steel.

Anti-corrosion protections - the designed cabinet is used for drying of working and protective clothing as well as ventilation. As the result of the cabinet's operation, water vapor is produced, which is in turn discharged outside of the cabinet (no condensate is created). The cabinet is to serve its user for many years, it operates in difficult conditions, the cabinet's assemblies cannot be susceptible to humidity and its structure - to accelerated corrosion. Therefore, unlike other cabinets, our cabinet has double anti-corrosion protections: they are made of zinc-coated steel metal sheet, and then they are electrostatically painted.

Heating and ventilation unit and the controller of work is located at the top of the ceiling of the cabinet; This protects against accidental damage and is also safe for the user of the cabin.

When you turn on the cabinet to work, air is drawn through the turbine-fan from the immediate environment through openings in the cover of ceiling and then the air is being pushed into an electric heater. The heated air is directed - with high speed -downwards towards the floor, and then is reflecting back from the floor upwards. This drying process works on the content which is to be dried not only from the top, but also from the very bottom; turbulent air flow penetrates into every possible nook and cranny of the charge which is to get dried.

At the same time the separation of the air occurs in the cabinet. Portion of the air is directed outwards - by the way the moisture is being outputted from the cabinet to the ventilation duct - and the remaining part of the air is re-introduced into circulation. The turbulent flow of air causes, that the drying process is precise and relatively short (and therefore economical).

DATA OF DRYING CABINETS type SSO MANUFACTURED BY ZPUG IZOTERMA | |||||||||||||

| No. | Type | Dimension (mm) | Power kW | Fan | Static press. Pa | No. doors | Weight kg | V -m3 chamber | Capacity (amount of clothes)* | ||||

| B | G | H | Ø | Power W | m3/h | ||||||||

| 1. | SSO- 60 | 600 | 600 | 1825 | 100 | 1,5 | 46 | 240 | 64 | 1 | 57 | 0,58 | 6 |

| 2. | SSO- 80 | 800 | 600 | 1825 | 100 | 2,0 | 46 | 240 | 64 | 2 | 66 | 0,77 | 8 |

| 3. | SSO-100 | 1000 | 600 | 1825 | 100 | 2,0 | 46 | 240 | 64 | 2 | 76 | 1,00 | 10 |

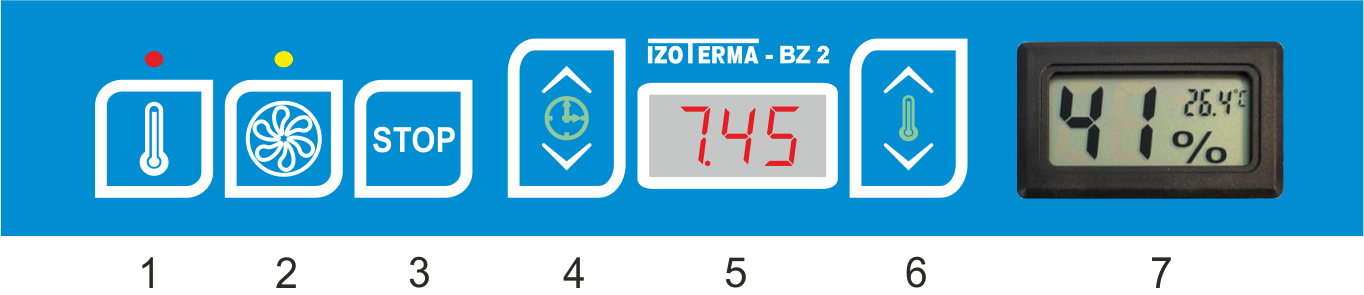

Izoterma – BZ2 – Electronic intuitive controller for programming of: time, temperature; humidity indicator.

Controller description

- Switching the heating ON

- Switching the fan ON

- Turning off the cabinet

- Setting time every 15 minutes up to 8 hours.

- Display: time and temperature – programmed and actual

- Setting temperature from 10 °C to 50 °C

- The humidity indicator and the exhaust air temperature

Gallery

Other drying cabinets

- Drying and disinfecting cabin type KSD

We reserve the right to make design changes to our products. The website is for informational purposes only and does not constitute a commercial offer within the meaning of Article 66, Paragraph 1 of the Polish Civil Code.

CONTACTO

NÚMERO DE TELÉFONO

+48 71-318-58-95

+48 71-318-58-96

CORREO ELECTRÓNICO

izoterma@izoterma.com.pl